[easingslider id=”374″]

EES supports it’s customers with all of their engineering requirements. Our experienced staff can help at any point in the engineering process:

- Clean sheet concept to application review.

- In house prototyping

- Designs compliant with emission, noise, or performance standards

EES will assist you every step of the way.

In-House Engineering Capabilities

Muffler exhaust system designs that emphasize:

- Cost effective solutions

- Durability and design intent

- Modular system designs

- Engine and application performance

- Performance acoustics

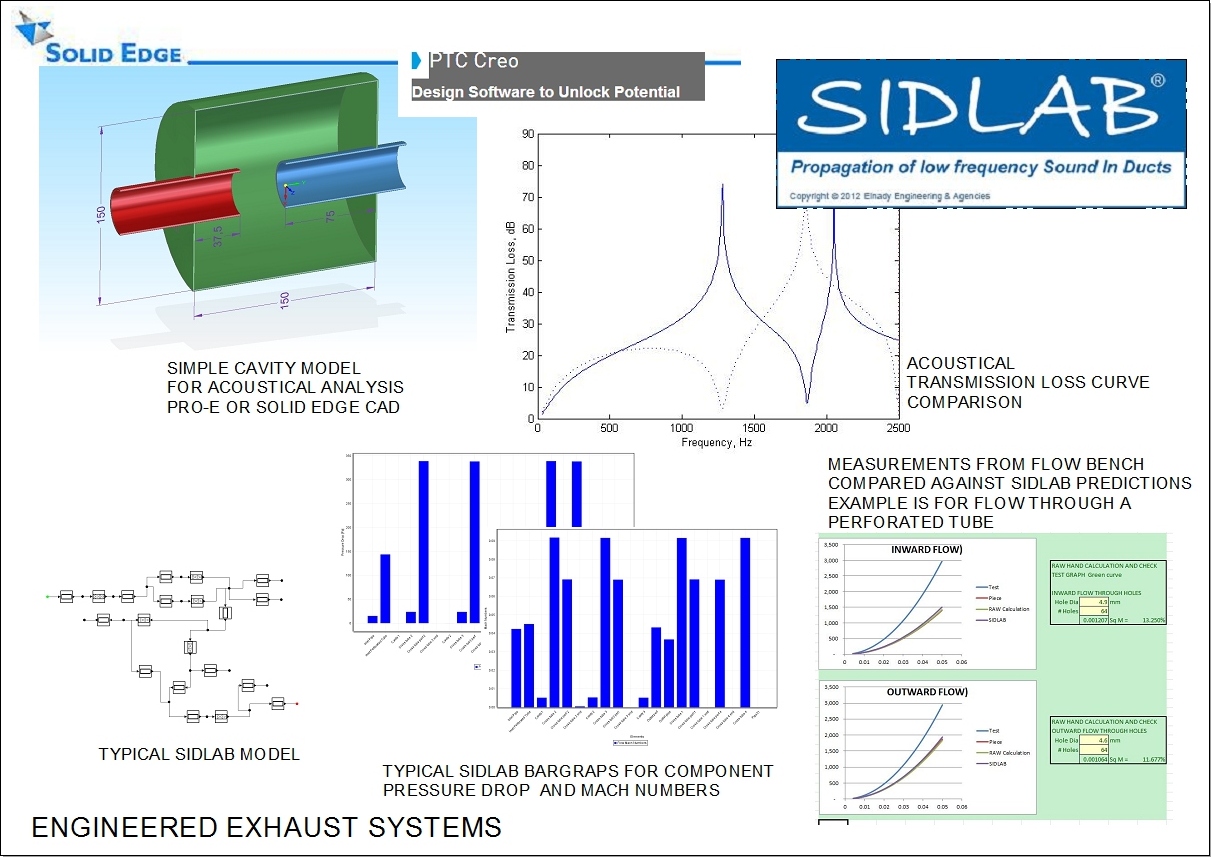

Design Software and Testing

Capabilities through our Manufacturing Partners

Tooling and Die Design

- Cost effective tooling programs using our in-house tooling capabilities

- Stamping tools

- In-house tube mill

- Tube forming and perforation equipment

- Fixture design

- ‘Life of product’ tooling maintenance

- Catalyst development

Prototyping

- Low volume pilot runs

- Laser cutting

- Programmable turret presses

Product Assembly